Cigar Box: How to Build a Beer Can Microphone

So you’ve built a cigar box guitar, eh? Want to add some vocals while you rock the box? Then let’s build a beer can mic. I’ve built several of these, and they have a great, old-time sound that’s even better with a little gain.

Want to add some vocals while you rock a cigar box guitar? Then let’s build a beer can mic!

I’ve built several of these, and they have a great, old-time sound that’s even better with a little gain.

Here’s your recon mission:

• 24-ounce beer can (Soda cans work too)

• Piezo disk element

• Metal sink drain strainer

• A piece of scrap wood the length of the beer can

• Volume pot (volume control). I like the 500k, but 250k will work too.

• ¼-inch phone jack

• Volume knob

• Bits of electrical wire

• Electrical tape

• Duct tape (Oh, yeah)

• Three each, 1/2-inch wood screws

The tools:

• Work gloves

• Safety goggles

• Tin snips

• Sandpaper

• Belt sander (optional)

• Screwdriver

• Soldering iron and solder

• Drill with 3/8-inch and 9/32-inch bits

As always, check out the Everything for a $1 stores and thrift stores for your gear, and check out CB Gitty for the piezo, jack and volume pot.

After you have emptied your can or can(s), give it a good wash inside and out and make sure it is dry. I use the 24-ounce can because, well, it’s 24 ounces — and it fits a little neater with the sink strainer.

Caution: This is dangerous! Be careful while doing this part. While wearing thick work gloves, carefully cut out the top of the can using tin snips. I use a belt sander with fine-grit paper instead of tin snips for this because it gives it a clean, smooth edge. I just set the can on the belt sander until it sands through the seam on the top of the can. Either way will work; just make sure to sand all the sharp edges.

AND REMEMBER: BE CAREFUL!

Next, use a 3/8-inch drill bit to make a hole for the jack on the bottom of the can. Then, halfway on the side of the can, use a 9/32-inch bit to make a hole for your volume control.

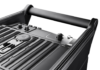

In terms of wiring, please refer to the photo to see how to solder it up.

Notice the volume pot or control has been sanded a bit so the solder sticks. From right to left on the volume pot is: positive wire from the piezo disk, positive wire to the jack, common ground that I bend back to the back of the control and place some solder on it to act as a ground.

I solder two ground wires to the back of the volume pot. One wire goes to the jack and the other will ground to the sink strainer. Notice all of the ground wires have been soldered to the back of the volume control.

Now connect the jack, volume pot and our “stick” in the can. I secure the “stick” to the can with two wood screws.

Let’s remove the pin and the rubber stopper from our sink strainer and place it on top of our mic. I secure it with a wood screw and wrap our ground wire around the screw so the mic is grounded.

Next time, we will have a clip of some folks giving it a test drive, along with our next project — a cigar box stomp — to add a little percussion while playing your CBG (cigar box guitar).

Keep on playing …

NOTE: This mic has an old-time crystal mic or harmonica-style sound and is meant to be used through a guitar amp. I would not recommend using this directly in a PA system.

Brian Saner owns Saner Cigar Box Guitars, which makes custom handmade guitars and amps using local dry-aged wood in every guitar. These guitars are handmade and might have imperfections, but that’s what makes them unique. Once you hear the howl of a CBG, you might not want to play a Fender or Gibson again. Get one at sanercigarboxguitars.com, devildownrecords.com/guitars and Main Street Gallery. Check out his Facebook page.

Source: www.guitarworld.com